This video shows what happens during the centrifugal casting process. X 13 330 HEIGHT 1200 LBS 544 Kgs.

The design and fabrication of a centrifugal casting mach ine was successfully carried out.

. We manufacture a full range of horizontal vertical and dual faceplate centrifugal casting machines. Nathan janco founded centrifugal casting machine company in 1940. They are provided with the systems of a programmed controlled crystallization to obtain alloys with the required properties.

After the static casting is finished the newly casted roll will be positioned in the ground pit for curing for 24 hours in a certain degreed temperature. Casting machines with a vertical axis are employed for manufacturing of relatively short ring castings of any complexity. We invite you to browse through our web site to view the types of centrifugal casting machines that we manufacture or click here to download a brochure.

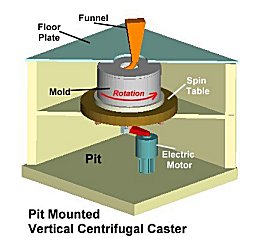

MACHINE MODEL AVERAGE MAXIMUM CASTING DIAMETER X HEIGHT MAXIMUM LOAD VP500 16 406 OD. A typical vertical centrifugal casting machine is shown in Fig. The centrifugal casting machine has two chambers the upper and lower chambers.

We offer both standard machine designs as well as custom machines to meet your project specifications. This method is more suitable for these bodies when the diameter is greater than their length. What is vertical centrifugal casting.

Gibson Centri Tech Limited design and manufacture three distinct ranges of vertical centrifugal casting machines. Melting of high temperature metals takes place in the upper chamber the molten metal then flows into the lower chamber where the hardened investment flask has been placed. Our state-of-the-art equipment generates pressures up to 60 times the force of gravity to segregate and remove impurities.

Each is capable of producing castings for a variety of applications including roll making cylinder liners reformer tubes pipes bearings and bushes. For this purpose a special design of a vertical axis centrifugal casting machine was developed. Vertical centrifugal casting machine designIt might be hard to see with the bare eye as well as depending on your displays resolution but these super feminine and simplistic designs for short nails are actually white and mint with a bit chevron accented nail.

The design setup is reduce the construction cost of machine. The vertical centrifugal casting machines adopt fully automated systems utilizing programmable logic controllers PLC with functions of automatic pouring automatic mold coating automatic mold inner wall cleaning and automatic extraction. Vertical machines are often chosen to produce castings that are.

A detailed study of the centrifugal pouring process and the inherent fluid dynamics was performed to develop a conceptual design and operation parameters and. - This type of casting is followed for cylinder type bodies having ring geometry. This is the new ebay.

Tulsa Centrifugal Casting Machines LLC -USA PO. X 12 305 HEIGHT 1000 LBS 454 Kgs VP1200 22 560 OD. Areas using centrifugal casting.

The machines have the elastic-damping. Box 702751 Tulsa Ok. With 90 of our work exported we are a global supplier.

It is basically used for casting small hollow cylindrical components. A detailed study of the centrifugal pouring process and the inherent fluid dynamics was performed to develop a conceptual design and operation parameters and inputoutput system variables were established. Find Centrifugal Casting Machine now.

Vertical Centrifugal Casting Machines Further Information. We invite you to browse through our web site to view the types of centrifugal casting machines that we manufacture or click here to download a brochure. Vertical centrifugal casting machines installed below the ground level for maximum operator safety are used for producing bushings and castings that are relatively large in diameter and short in length.

The operation of the machine was based on the principle of. Please visit the following links for more information or email our sales. Tulsa Centrifugal Casting Machines LLC -USA PO.

The casted products diameter ranged from 50mm to 2000mm with length ranged from 50mm to 2000mm. This paper analyses and discusses all of the referred design phases including selection and prototype implementation of the necessary actuators. When this stage is complete it is time to remove investment from your newly cast jewelry.

Each machine series is designed to handle a specific range of castings sizes and weights. In this method the mould is rotated in a vertically axis. Box 702751 Tulsa Ok.

Animation showing what happens during the vertical centrifugal casting processTo learn more about the centrifugal casting process visit us at httpswwwm. This project led to the design and construction of true centrifugal casting machine which is made of mould shaft belt pulley bearing motor. For this purpose a special design of a vertical axis centrifugal casting machine was developed.

Ad Over 70 New. Vertical centrifugal casting machines. The first step is the vertical centrifugal casting of roll shellouter layer the second step is the vertical static casting of roll core.

The mould spinning speed depends on the casting desired. Our vertical centrifugal casting techniques produce gear blanks with high purity density and durability. Vertical centrifugal casting machines can be used to cast both ferrous and non-ferrous materials and come equipped standard with water cooled shafts and variable speed drives.

The two steps are proceeded continuously in sequence. Centrifugal casting consists of a number of processes in which the centrifugal force set up by the rotation of a part of the casting is utilized to shape the casting fill the mould and help solidify and strengthen the metal Pavlovic et al 2009. High g-forces applied to the molten metal in the.

X 9 228 HEIGHT 500 LBS 227 Kgs VP1000 20 508 OD. We offer both standard machine designs as well as custom machines to meet your project specifications. This article discusses the mold design for different types of sand molds and permanent molds and their production considerations.

There is a difference between vertical centrifugal casting and horizontal centrifugal casting.

Tulsa Centrifugal Casting Machines Vertical Machines

Vertical Centrifugal Casting Machine

Schematic Of The Vertical Centrifugal Casting Machine Huang Et Al 16 Download Scientific Diagram

Pdf Design And Development Of A Centrifugal Casting Machine For Pistons Production Semantic Scholar

Pro E 3d Model Of Centrifugal Casting Machine Download Scientific Diagram

Tulsa Centrifugal Casting Machines Vertical Machines

Constructive Scheme Of A Centrifugal Casting Machine With A Vertical Download Scientific Diagram

Vertical Centrifugal Casting Machine Download Scientific Diagram

0 comments

Post a Comment